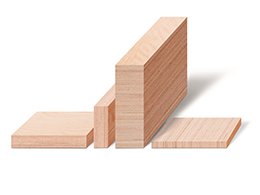

BauBuche is a laminated veneer lumber made from locally sourced beech manufactured exclusively by Pollmeier. BauBuche is produced in a completely new, yet highly economical process. Peeled veneer layers of 3mm in thickness are parallel- or cross-laminated and turned into beams, boards, panels and flooring elements.

With its exceptionally high strength BauBuche allows structures with significantly slimmer dimensions, compared to softwood materials. The high surface quality makes BauBuche ideally suited for visible construction Elements.

About BauBuche

- Extremely versatile

- High load-bearing capacity combined

- Suitable for large spans

- Exceptional surface quality

- Locally sourced raw material

Beam BauBuche GL75

BauBuche GL75 is made from 40 mm thick BauBuche S laminations, bonded parallel to the grain. Its high strength allows BauBuche GL75 to be used in slender structures for heavy loads and large spans.

The side surfaces of BauBuche GL75 show the attractive veneer layers, while the top and bottom show the hardwood surface. BauBuche beams are sanded at the factory, and are ideal for exposed structural Elements.

Board BauBuche

Board / Beam BauBuche S

BauBuche S is mainly used in the production of bar-shaped components. For this purpose the boards are cut lengthwise into strips with a cross-section of up to 60 mm width. BauBuche S is currently available for non-visible applications, quality for visible applications on request.

Board BauBuche Q (lead time on request)

BauBuche Q is available including approx. 15% of cross layers. It is mainly used for larger structures such as load-bearing wall elements and as a part of joint components, e.g. hollow box beams or ribbed base plates. The cross layers ensure that even large panels are highly resistant against warping. The cross-layers make sure that even large panels have high resistance against warping.

BauBuche Board is suitable for:

- Bar-shaped components (BauBuche S)

- Flat supporting Elements (BauBuche Q)

- Length: up to 18.0 m

- High load-bearing strength

Board BauBuche S

Thickness

40, 60 mm

Width

100, 120 ,160, 200, 240, 280, 360, 400, 440, 480, 520, 560, 600, >600-1820 mm

Length

6‘000, 12‘000, 13‘500, 16‘000, 18‘000 mm

Longer lengths, special lengths

On request

Board BauBuche Q

Thickness

40, mm

Width

1820 mm

Length

6‘000, 12‘000, 13‘500 mm

Longer lengths

On request

Neue Holzbau AG stocks a wide range of BauBuche panels for the production of customised girders.

Thanks to a modern machine park for various joining technologies, orders can be fulfilled within short timeframes. The multi-machine concept enables us to choose the best machining option for each construction component.

We assist you of course in the assembly and installation of the elements. Advanced CAD/CNC technology and time-saving GSA fasteners allow for efficient installation and alignment on site.

BauBuche & GSA-Technology

BauBuche is an innovative high-quality material with unrivalled strength and load properties made from sustainable resources. GSA-Technology offers builders optimised joining solutions of the latest generation: high-strength fasteners that are not only ductile but also completely concealed. BauBuche and GSA are a perfect team.

Greater efficiency and economy

Use BauBuche and GSA-Technology to achieve larger spans and slimmer lattice girder constructions. The unique finish of the top-grade hardwood material and the concealed fasteners allow for timber constructions of a new aesthetic quality. Minimum wastage and the time-saving production help save money.

Make your Projects more cost-efficient – we Show you how

See how much you can save with a BauBuche-GSA support structure compared with a conventional steel, concrete and softwood construction. Our sales reps would be delighted to calculate your project costs and provide you with an attractive offer.

GSA-Technology – the perfect fastening system

Developed by Neue Holzbau AG in cooperation with Professor Ernst Gehri from ETHZ, we have been using GSA-Technology for more than two decades. Today, there are more than 2000 projects worldwide where GSA-Technology is the main fastening method.

To obtain the required approvals with minimum delay, we perform the necessary tests in our own lab. GSA-Technology is constantly improved and developed further by our R&D Team.

Advantages of GSA-Technology at a glance

- Standardised system: High availability and short delivery times.

- High degree of assembly: Excellent precision and quality at an affordable price.

- Architecture: Virtually invisible joints for aesthetically pleasing designs.

- Fire safety: Protected fastening elements for improved fire safety.

- Efficient on-site assembly thanks to push-in GSA fastening Elements.